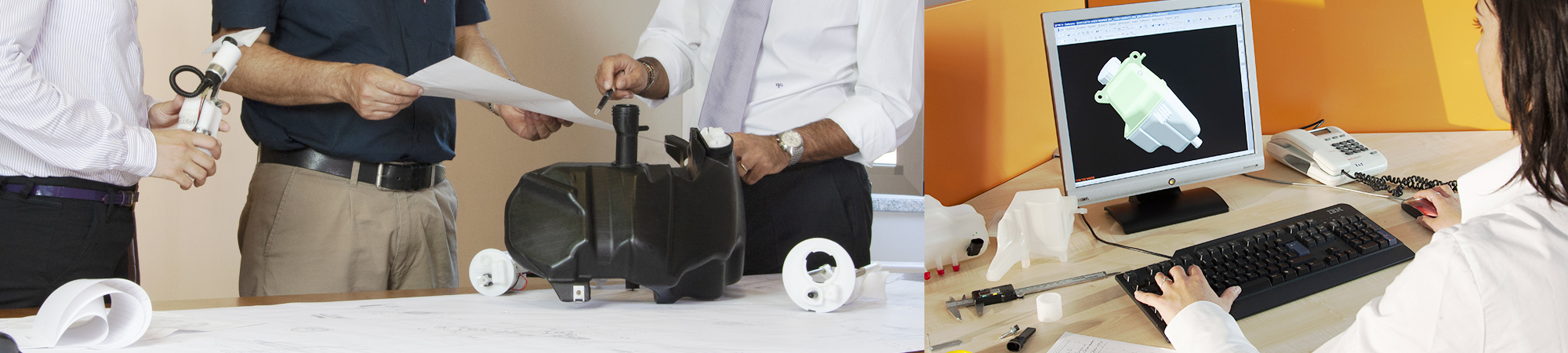

DESIGN & PROTOTYPING

The Par.Co. uses parametric solid modeling systems,and collaborates with customers for the development of new products and innovative production processes.

Through the knowledge and experience of its technicians, it carries out feasibility analyzes and verification of the behavior of the product under thermo-mechanical stress through FEM, vibrational or fluid dynamic structural analyzes.

Par.co is able to start rapid prototyping (soft tooling) in a short time. This activity allows the customer to carry out, before starting the construction of the definitive equipment, all the functional checks and the validations with quick-made products and very low tooling costs.

MOLD CONSTRUCTION

Par.Co. owns an internal tooling shop for the construction of molds, equipped with high-speed machining centers and EDM driven by automatic programming systems.

Par.co produces both high-precision technical molds for high production, in tempered steel and aluminum, and pilot molds in aluminum for the production of functional prototypes and pre-series parts.

Par.Co. can rely on knowhow and competence of its experienced staff.

LABORATORY CENTRE

Tests carried out on materials:

- Melt Index Flow rate

- VICAT/HDT

- Melting temperature

- Rockwell, Shore A D hardnesses

- IZOD

- Traction and elongation

Tests carried out on components:

- Simulated aging in temperature and pressure

- Thermal cycles

- Dimensional stability

- Leakagr tests

- Burst tests

- Tests of resistance to depression

Metrology:

- 3D measuring with probe and scanner