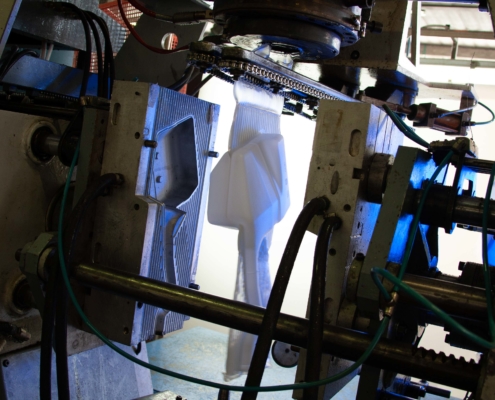

BLOW MOULDING PRODUCTION

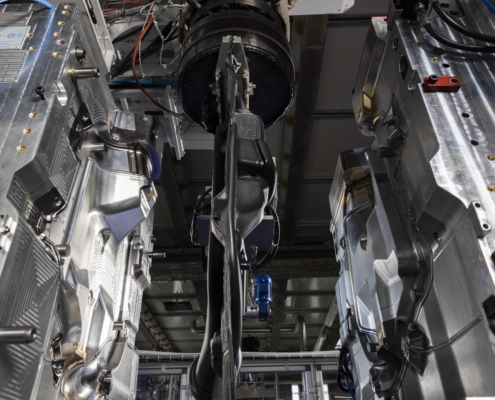

Par.co. manufactures ventilation ducts, headlight washer fluid tanks and oil tanks

using modern and versatile blow molding technology systems with continuous extrusion and accumulation head, with closing force from 10 to 50 tons.

All blow molding machines are equipped with thickness adjustment systems and drilling and welding systems.

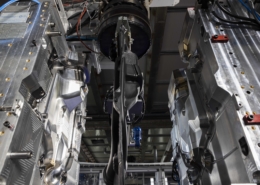

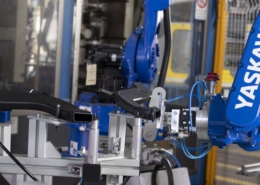

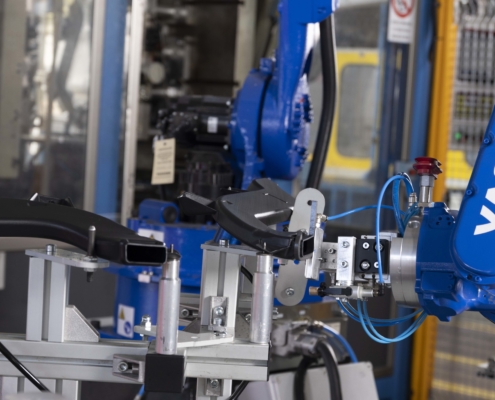

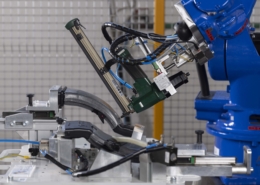

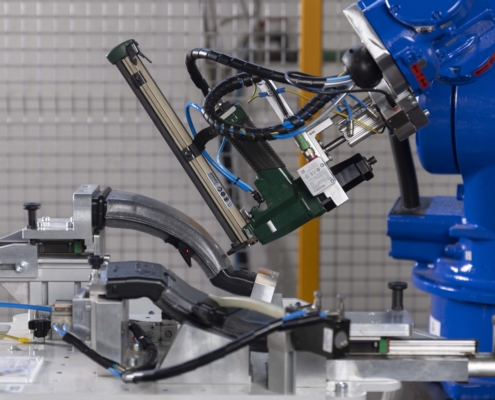

Anthropofomorphic manipulators are used for picking up the blow molding machines, removing the product and assembling the components.

Checks are carried out on products through optical image processors.